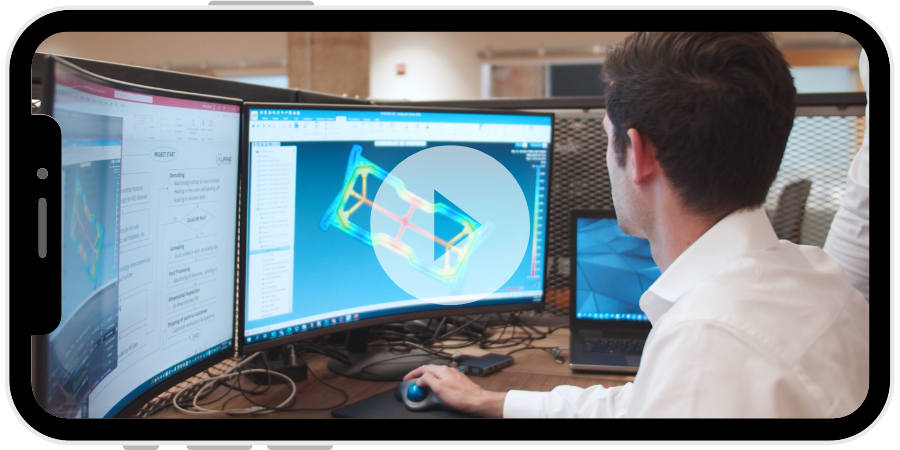

OUR product design and prototyping services are changing the way the most demanding industries innovate.

Concept Through Production

Our experts offer a high-touch experience from the earliest stage of a project through its production lifecycle, streamlining the process through one partner.